Abstract: A need for low-cost warfare has emerged from the experiences of several nations in current conflicts. On the one hand, a recent missile and drone attack on Israel was successfully defeated, but at the unsustainable cost of an estimated $1-1.5 billion. Houthi drones, costing $2000 each, were successfully intercepted with Standard Missile-2s (SM-2), which cost $2 million each. On the other hand, the Russian Black Sea fleet was severely degraded by sea drones costing between $250 and $ 350,000 each. There are two consequences deriving from this: There is an urgent need for low-cost systems both in defence (to counter the Houthi-type attacks, for example) and offence (to engage in sea control or with combat drones as an artillery substitute).

Problem statement: Based on the past and current experiences in drone warfare, what could be the potential of Additive Manufacturing in drone manufacturing?

So what?: The potential of AM in the mass production of drones has yet to be realised. Before full potential can be reached, certain challenges need to be overcome. First of all, drones have to be introduced into strategic, operational, and tactical concepts to foster the development of a framework for use and, hence, more detailed production necessities.

Source: shutterstock.com/Dizfoto

The Importance of Unmanned Autonomous Systems in Future Warfare

Unmanned autonomous systems (UAS) have become critical to war, be it on land, in the air, or at sea. The roles assigned to these systems include reconnaissance and attack as well as support functions—for example, medical applications. Although there are divergent perspectives on their importance,[1] there is no doubt that the massive application of drones will be a part of it, regardless of whether they are decisive in future battles or not.[2] Compared to the use of drones in the conflicts in Libya and Nagorno-Karabakh,[3] the scale and range of drone uses and applications have increased tremendously: Ukraine alone produced 1.5 million First-Person-View (FPV) drones in 2024. It dedicated $1.2 billion in 2024 for drone procurement, with about $480 million for long-range drones, of which 30,000 should be produced in 2025.[4] For 2025, drone production contracts worth $3.58 billion with a slot number of around 1.8 million drones of various types have been issued.[5]

In addition to FPV, air, and sea systems, Ukraine is testing land-based walking drones with its 28th Mechanised Brigade in Toretsk[6] as well as a British model called “BAD One”.[7] Other types of ground drones, wheeled or tracked, are also widely used, for example, by the 47th Mechanised Brigade in Kursk Oblast. They are used for multiple purposes: logistics, medical evacuation, laying mines, and mobile gun platforms.[8] In adapting UAS to these roles, the Ukrainian Armed Forces have elevated drones from a supporting role to a central operational asset; this shift is best displayed in the establishment of the Unmanned Systems Forces by presidential decree in 2024.[9]

Of all these systems, 96.2 % were produced in Ukraine by local industry.[10] Furthermore, the dependency rate of parts being delivered from abroad—especially from the People’s Republic of China (PRC)—has been constantly reduced. This reduction is not only due to increasing Chinese export restrictions but also to an increasing lack of reliability, intentional or not.[11] Testament to this is the existence of a 100% Ukrainian-made drone.[12]

Ukraine’s experience demonstrates that there can be no doubt that drones will play an important role in future warfare. It is also reasonable to assume that armed forces, which rely on expensive winged drones for reconnaissance, artillery and air strikes, will suffer significant losses against an adversary experienced in drone warfare. It is, therefore, paramount to have the capabilities and capacities to produce the numbers for extensive and long-lasting use of drones across multiple roles.

Ukraine’s experience demonstrates that there can be no doubt that drones will play an important role in future warfare.

European states, which are not at war nor frontline states, have a certain luxury in preparing themselves not only to defend against but being able to wage that kind of warfare should it become a necessity. Unfortunately, in European states such as Germany, the focus in the past on defence procurement was on quality and technically very sophisticated systems instead of mass production. Today, Germany—and Europe—is unable to produce vast numbers of smaller UAS quickly.[13] Moreover, there is a necessary pre-condition that is also not met for mass production: Drones, as used in Ukraine, are only slowly becoming part of NATO operational concepts, doctrines, field manuals, and those of its members. Neither NATO nor its members have comparable experience with drones as Ukraine, where mass use is executed at all command levels—platoons, companies, battalions. Nevertheless, the importance of drones in future conflicts demands the capacity and capability to produce drones in vast numbers.

The German National Security and Defence Industry Strategy as a Starting Point

The importance of looking not only at technology and doctrines but also at production, both in terms of time and capacity, started in Germany with the “Strategy Paper of the Federal Government on Strengthening the Security and Defence Industry” in 2020: “To maintain control over technologies that have already been identified but will not be relevant for productive use on a large scale until some point in the future” is essential.[14] In light of the war in Ukraine, the newly introduced strategy of 2024 highlights the importance of a resilient, effective and sustainable defence industry: “To be able to draw on sufficient production capacities without delay, to increase economies of scale and enable innovations, we strive to achieve a continuous production of military equipment by the security and defence industry.”[15] This strategy outlines the challenges and the must-dos regarding matters of production, both in terms of capacity and agility/flexibility.[16] Although this strategy highlights certain aspects of what is and will be of importance regarding manufacturing, the strategy itself offers no clear advice on how to achieve this.[17]

Unlike Ukraine, states like Germany have the luxury of being in a position where such drone innovations can be safely undertaken in a planned manner within a relatively reasonable time frame. Additionally, insights from the battlefield can be automatically incorporated into planning and production cycles; this applies to technology, procedures, and processes.

Current Developments in Drone Manufacture and Use

To identify how best to address the above-described challenge, defence planners need to take a deeper look at the current trends in drone manufacturing. These developments are, until today, not dependent on the outcome of our initial discussion if drones are a game-changer or not. More importantly, strategy outlines like the German one described above, operational concepts like “Hellscape”,[18] and actual ongoing initiatives like the US “Replicator” initiative[19] or the local defence industry initiative “Brave1”[20] in Ukraine are relevant. All of these initiatives show that drones in multiple roles, in different domains and mass numbers will be an element to be considered in future warfare.

Strategy outlines like the German one described above, operational concepts like “Hellscape”, and actual ongoing initiatives like the US “Replicator” initiative or the local defence industry initiative “Brave1” in Ukraine are relevant.

The developments in drone warfare connected to the production process, starting with Libya and Azerbaijan, and very dominant with current developments in Ukraine, can be summarised as follows:[21] Regarding the number of drones produced and used, it is increasing with no end in sight. At the same time, the use rate of one-time compared to multi-use drones is increasing as well. However, there is an increasing variability both with regard to their roles and the technical modifications. This experience corresponds to the perception of drones as low-cost ammunition instead of mere delivery/observer weapon systems. On the cost side, a degressive trend was visible for some time. However, it will most likely peak in the near future because of new features to be added (more stable connection, resilience to Electronic Warfare, night/thermal vision). The production of drones in wartime has changed, shifting from industrial to artisanal (ordinary garage or workshop solutions), often crowd-funded.[22] The parts for the drones are mostly available on the global market, and their purchase cannot be limited through export restrictions due to their common utility in various other non-military goods.[23] At the same time, there is a shift from off-the-shelf to tailor-made drones[24] designed for specific needs and tested on a trial-and-error basis (with regular and timely feedback loops established between the producing industry and the military).[25] The next step on its way is the use of Artificial Intelligence (AI), although still at a very early stage. Initial projects indicate the use of AI for target identification; this is particularly useful amidst camouflage and differentiating fake from real targets.[26] AI is also used in as well as marking and recognition in case of loss of connection to the pilot—most often on the last 200 m.[27] A newly developed model (HX-2) from the German start-up Helsing should be able to guide drone swarms.[28] Until now, AI has not been used for target selection/prioritisation, but this is likely forthcoming.

One final trend is notable: more and more separate drone-specific units are being established as units in their own right rather than being embedded within other military units. Additionally, the level of designation for separate drone units is coming down: drone companies can be found at least at the brigade level, but more and more at the battalion level as well.

The establishment of separate and independent drone units, combined with the down-levelling of their attachment, creates new necessities regarding supply chains and local workshop capacities for repairs and modifications. The same logic can be found in other developments, such as the Iranian ship the Martyr Bahman Bagheri. This is a container ship converted to use as a drone carrier, which can house up to 60 drones.[29] It is valid to assume that modification and repair facilities are installed directly on board.[30]

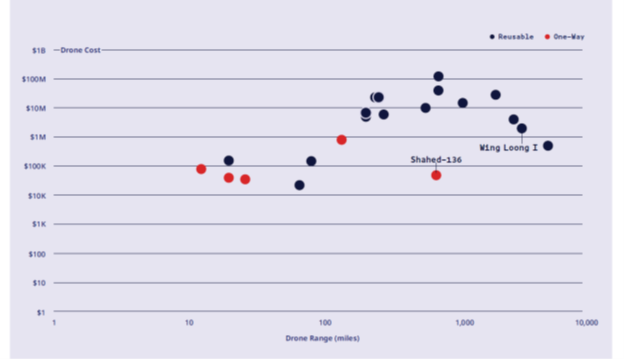

One of the most important aspects is the production costs, where the cost-per-unit matters for decision-makers, as extremely large charges are being discussed.[31] In cost-benefit analysis, the cost-effectiveness offered by drones cannot be denied. The war in Ukraine offers ample evidence of this, such as the sinking of the $65 million patrol ship Sergey Kotov by “Magura V5” drones, costing only $273,000 each.[32] This drone is also responsible for sinking up to 9 Russian ships in total.[33] On land, this cost-effectiveness was seen in the destruction of a $15 million Tor-M2 Radar Unit by a $500 Switchblade FPV.[34] A last example regarding planes was the destruction of a $100 million TU-22M3-hypersonic bomber by a drone.[35] However, mass production demands a cost-per-unit analysis. Looking at Ukraine again, in the beginning, Chinese off-the-shelf drones from DJI were used for reconnaissance purposes, costing from $1,500 to $5,400 (thermal night vision capable). They were used especially to direct artillery fire.[36] At the same time, longer-range drones are used for deep strikes, substituting for the lack of cruise missiles and airborne assets—the costs of those drones are much higher:[37]

Source: S. Pettyjohn/ H. Dennis/ M. Campbell, “Swarms over the Strait – Drone warfare in a future fight to defend Taiwan,” Centre for a New American Security, Policy Paper June 2024, https://s3.us-east-1.amazonaws.com/files.cnas.org/documents/Indo-Pacific-Drones_DEFENSE_2024-final.pdf, last seen 25.02.2025, 55.

Later on, with the lack of sufficient amounts of artillery shells, FPV came up in vast numbers. Today, the 10-inch Vyriy-10 drone costs about $409. The newly developed prototype of a 100 % Ukrainian Vyriy drone costs $503.[38] The prices can be expected to go down, as with the other already existing models in mass production. The most inexpensive drones cost around $200-250.[39] Other models, for example, heavier drones used for dropping grenades and mortar bombs, range from $1,000 to $10,000.[40]

The basic model of the walking Cyber-Dog drone costs $1,600.[41] A new application is the use of a winged drone as a carrier for the FPV, which therefore increases their operating radius to 50-60 km instead of 25 km before. They serve at the same time as repeater drones for radio signals, which lessens the impact of hostile electronic warfare (EW); such drones can be bought commercially and cost around $8,000,[42] some of them even less (around $2,700).[43] The cost-effectiveness of these drones is very high, even considering efficiency. The cheapest drones have an efficiency rate of only 10-15%, and more advanced FPVs in the range of $300-400 achieve a 30% efficiency rate. Even if it needs 20-30 less expensive drones to destroy a target (be it a vehicle, a tank, fuel, etc.), it is often worth the investment (3-6 drones with a cost equivalent of $900-1,800 to guarantee a kill). In fact, more than two-thirds of Russian tanks have fallen victim to drones.[44] Even targeting individual soldiers (who are trained and equipped) is considered cost-effective, as they are much more difficult to replace compared to FPVs.

More than two-thirds of Russian tanks have fallen victim to drones. Even targeting individual soldiers is considered cost-effective.

Further, as a pilot has about 40-50 minutes of flight time and knows that there is no chance of returning a $500 kamikaze drone once it is armed, the pilot will hit any target over $1000 or lose the drone. Moreover, the nearer it gets to the end of the in-flight battery capacity drained, the cheaper the price of the target gets. With only 1% of battery power left, anything will be hit to make sure the drone is not wasted: “Any enemy target more valuable than $1,000 identified by a drone pilot will be hit without hesitation, as this creates a favourable cost-benefit balance.”[45]

Additive Manufacturing (AM) as a Potential Contribution

Additive manufacturing (AM)—popularly known as 3D printing—is the process of creating an object by building it one layer at a time. It is the opposite of subtractive manufacturing, in which an object is created by cutting away at a solid block of material until the final product is complete.[46] Logistically, there is a substantial difference between the supply chains of traditional and additive manufacturing:[47]

Source: T. Kruemberg, “Bringing significant rapid manufacturing capacity into the Armed Forces logistics chain,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, 17./ 18. October 2023, Bonn, 6.

The differences between these lead to several potential advantages: Firstly, there are potential savings in developing prototypes (estimates range to 85% time and 80% cost savings).[48] Second, savings are realised during the production process, be it in the production of prototypes or serial production, as weight reductions, as well as a customised and high mix/low volume production, can be realised. Additionally, there is higher flexibility through just-in-time production and small batch sizes and higher speed as fewer tools are needed, and on-demand production can take place. A higher degree of customisation, a higher degree of complexity, and even a higher rate of repeatability are possible as well.[49] Third, there are savings in the overall replacement costs.[50] This includes shipping and costs attached to the inventory level.[51]

Looking at AM for the purpose of addressing military needs, several trends are evident:[52] AM’s potential is being looked into by several Armed Forces, and several pilot projects and evaluations have already taken place.[53] The U.S. has already adopted a fully-fledged strategic approach to the use of AM.[54] Several use cases have shown that mobile AM is possible, even in difficult environments typical for armed forces.[55] Although there are limitations on the accuracy due to transport and vibration resistance, plenty of parts can be produced within acceptable tolerances. There are examples of mobile factories in a 20-foot TEU with a production and a logistical support unit (e.g. scanner for reverse engineering), sometimes airborne capable (e.g. from Xerion on the ENOK AB).[56]

AM’s potential is being looked into by several Armed Forces, and several pilot projects and evaluations have already taken place.

The German Armed Forces operate a modular concept consisting of the so-called eAFE (a light AM unit), AFE (AM unit), vAFE (moveable AM unit) and AFZ (AM centre).[57] Norway operates a similar concept.[58] Applications encompass expedient repairs, battle damage repairs, temporary replacements, and modifications, e.g. to realise modifications depending on the intended use of existing drone frames. That is why there are already 3D printers in the workshops of every drone unit.[59]

However, depending on the purpose for using AM, there are issues of legal relevance to consider because, typically, AM requires scanning the original part to create a CAD file [60] or transferring an existing CAD file from the original equipment manufacturer (OEM).[61] There is relevance regarding intellectual property rights, warranty situations, statutory warranty rights and common liability situations.[62] There might also be issues with export control regulations, as is the case, for example, with the U.S. International Traffic in Arms Regulations (ITAR).[63]

Nevertheless, AM has to be considered more strongly for procurements and tendering processes.[64] Common standards, which are aligned with industrial standards, are the basis for common recognition, which is the basis for mutual logistic support. Operational availability of assets has priority, which can lead to a conflict between OEM quality vs. functionality.[65] Performance-based, multisource contracts and the replacement of procurement documents with tryouts are being applied more often.[66]

Training necessities will likely arise to align current military AM operators with existing and developing standards as well as adapt them to the military context, quality management aspects (e.g. defect identification), and how to handle qualification, certification, and standardisation in critical scenarios.[67]

Furthermore, we contend that a new method of AM—AM electronics—should be integrated into AM practices. For example, the mesmeronic process chain, developed at the Fraunhofer Institut für Additive Produktionstechnologien, offers several advantages: Integrated conductor tracks which require fewer or no cables; embedded electronic components which reduce assembly efforts; a lightweight design which demands less material, and the possibilities of many varieties enabling rapid development.[68] With the use of carbon fibre reinforcements, a certain shielding against EW can also be achieved.[69]

The use of AI in production offers a range of potential applications through data-driven design based on genuine data, such as enhancing design and improving materials and processes.[70] In the manufacturing process, accuracy, speed, and simplicity should be increased. Hence, the scrap rate decreases, and tolerances are reduced for higher precision components.[71] Data-driven decisions will follow, e.g. machine settings pathway planning, post-processing precision[72]and quality control.[73] Ultimately, the cost per unit should be lowered through AI-driven decisions.

The use of AI in production offers a range of potential applications through data-driven design based on genuine data, such as enhancing design and improving materials and processes.

Research has confirmed that AM reduces costs and is economically sound. However, most applicable critical items are not produced by AM (e.g. microchips, cables, antennas).[74] In Ukraine, the role of AM in combat conditions is to produce fittings, modifications to drone structures, and casings for grenades with a high weight-damage ratio, as well as fins for homemade bombs.[75]

- Source: Author.

- Source: Author.

A major AM production line based on the available 3D printers close to the front cannot work at present, as drones are generally not delivered to combat units without prior flight testing, which cannot be done at the front.

Aspects to be Considered for Decision-Making

Current drone designs show that most parts can be pre-produced or stored without the danger of obsolescence between production, storage, and potential use. These parts can be counted as the frame, the propellers, the motors, the battery, the antennas, the electronic speed controller, the flight control unit, the video transmitter/receiver, and the camera board. However, the GPS and radio control transceivers need constant updates.[76] The frame, if pre-produced, has to have the ability to mount different fittings, and the printed circuit board and flight stack have to have the ability to host different and adapted controllers.

Current drone designs show that most parts can be pre-produced or stored without the danger of obsolescence between production, storage, and potential use.

Components are the main costs associated with setting up a traditional drone manufacturing business; these can account for 30-50% of total manufacturing costs.[77] Skilled labour is also necessary, and this can consume 20-25% of operational costs. The maintenance and repair of the machines and tools can run up to 5-10% of operational costs. Logistics and shipping add another 5-10%. Renting a facility can add another 10-15%. However, minor positions would be Research & Development, quality control, marketing, insurance, and other overheads.[78]

Of course, several more technical questions connected to traditional manufacturing as well as AM will be of importance: the lifetime of equipment, the assumed minimum shelf-life of materials, how weather and climate conditions influence the performance of equipment and materials, the mobility of the equipment and materials, the reliability of supply of equipment and materials, the maintenance intensity of equipment.[79]

Other areas are the manufacturing strategies (e.g. product design, manufacturing practice), supply chain and logistics planning (e.g. centralised/ decentralised production and distribution, lot sizing and inventory management), sustainability (materials, energy consumption) and the balance between depot- and field-level maintenance.[80]

Cutting-edge, Affordable, Ready

Historically, war has been a continuum of constant change, which drives technological innovation—this applies equally today. In the field of military production, the need for customisation, increased product functionality, and rapid prototyping, as well as full production chain competitiveness, must be quickly achieved. Consequently, production must be simplified, robust and deployable—or integrated into existing units, including ships and planes. The business model has to adapt to mass and customised production.

The maturation of AM has the potential to play a role in such a new manufacturing ecosystem. However, an AM-based manufacturing system or even a ‘lights-out’ factory-based model is neither feasible nor meaningful for drone production at present. As initially pointed out, outside of Ukraine, field manuals have not yet included the art of drone warfare; people are not trained, and drones are not introduced in large numbers. Yet, there is a massive production capacity as well as know-how in terms of technology, application possibilities, and active use in Ukraine.

The maturation of AM has the potential to play a role in such a new manufacturing ecosystem.

Conceptually and doctrinally, introducing drones should go in parallel with a massive increase in the number of drones available to armed forces; this could be done by relying on production capacities in Ukraine. Systems can be ordered in Ukraine, where strong investments in the domestic defence industry by German companies already exist. Additionally, in modernising European drone forces, supply and training contracts for soldiers and systems are needed urgently. They can also be realised by transferring current knowledge from Ukraine to other European countries, such as Germany, where certain companies already have working relationships with their Ukrainian counterparts.

There are several advantages attached to this kind of procurement. First, there is a lack of regulation in the area of drone production, which allows the quick scaling of efficient and cost-sensitive production. One does not even need any license to start producing drones and sell them; it is enough to register a company without any other permission needed. Second, the necessary workforce can be hired with service contracts without permanent employment, which allows businesses to appear and develop without high risks. Third, there is a lack of bans on flight tests, which are necessary and part of the production process. Fourth, any drone produced is counted as civilian production as long as no ammunition is attached, which enables faster export. Fifth, there is a lack of IP restrictions in the production of drones—because of the war, drone designers are patenting their drones. Ammunition containers, small parts and even long-range drones are already manufactured through AM. However, this production method is not suitable for one-way attack drones.

In addition, there is a need to start ordering critical parts that cannot be produced by either Ukraine or Germany in order to create a strategic stockpile. Right now, the existing supply chain from the PRC, U.S., and Taiwan is intact and can be used. However, those supply chains cannot be taken for granted, so self-reliant production capacities for those parts must be developed. As the outcome of the war in Ukraine is also unpredictable, a production capacity for all parts of drone manufacturing must be developed domestically. These production capacities could and should integrate AM into the manufacturing ecosystem. In the case of the need for domestic drone manufacturing on a massive scale through AM, intensive relationships between producers using AM, materials suppliers, and OEMs have to be established. A materials ecosystem with an open materials license and a contractual agreement with the OEM to buy ‘tokens’/ digital spare parts for printing or the digitalisation of existing components, including the re-certification of components, will be necessary to build up a digital inventory. In this respect, NATO has already achieved standard leadership.[81]

Furthermore, batches of experimental verification platforms in areas like key materials and major equipment need to be constructed. The provision of economically viable production capacities to such an extent, preferably with fixed quantities, can be achieved through the introduction of indefinite-delivery/indefinite-quantity contracts, whereunder partial orders can be placed and which compensate for idle capacity costs and serve as a kind of reserve capacity payments.

As a consequence, significant first-mover advantages could be realised while at the same time living up to the slogan “Cutting-edge, Affordable, Ready”.[82]

Dr Wolfgang Müller is a Senior Resident Research Fellow at the German Institute for Defence and Strategic Studies; his research interests include Total Defence, China, and the Weaponisation of Economics.

Dr Sergej Sumlenny is the Co-Founder and General Director of United Unmanned Systems LLC, a German-Ukrainian drone developer and producer; he is also the Managing Director of the European Resilience Initiative Centre.

The views contained in this article are the authors’ alone.

[1] For example, even in Ukraine, there is a plethora of perspectives—General Valerii Zaluzhny, the former Ukrainian Commander-in-Chief, sees drones as a game changer. In contrast, the Ukrainian Head of Military Intelligence, General Kyrylo Budanov, does not see such a decisive importance of drones (V. Zaluzhny, “Ukraine’s army chief: The design of war has changed,” CNN, February 01 2024, https://edition.cnn.com/2024/02/01/opinions/ukraine-army-chief-war-strategy-russia-valerii-zaluzhnyi/index.html; New Voice, “Drones will not bring ‘decisive advantage’ to either Ukraine or Russia, says HUR chef,” February 16 2024, https://english.nv.ua/nation/drones-have-been-in-full-use-by-both-sides-for-a-year-now-50393447.html; for a game changer see also: A.R. Hoehn/ T. Shanker, “Can cheap drones be the answer to tensions in the Taiwan Strait?,” RAND Defense News Commentary, June 2023, https://www.rand.org/pubs/commentary/2023/06/can-cheap-drones-be-the-answer-to-tensions-in-the-taiwan.html and B. Perrett, “Small, cheap and numerous – A military revolution is upon us,” The Strategist, January 22 2024, https://www.aspistrategist.org.au/small-cheap-and-numerous-a-military-revolution-is-upon-us/; for a non-game changer see also: R. Ruitenberg, “Small drones will soon lose combat advantage, French Army Chief says,” Navy Strategy News, June 2024, https://www.defensenews.com/global/europe/2024/06/19/small-drones-will-soon-lose-combat-advantage-french-army-chief-says/; AFP, “Cheap drones cannot match artillery power in Ukraine,” March 18, 2024, https://www.kyivpost.com/post/29670; U. Franke, “Drones in Ukraine – Four lessons for the West,” European Council on Foreign Affairs Commentary, January 10 2025, https://ecfr.eu/article/drones-in-ukraine-four-lessons-for-the-west.

[2] Ukraine announced that it will develop its own drone warfare doctrine. (TCH, “Ukraine to launch military project ‘Drone Line’ — Zelenskyy,” February 10 2025, https://tsn.ua/en/ato/ukraine-to-launch-military-project-drone-line-zelenskyy-2763612.html; China has launched its own drone program (G. Hondrada, “China leaks a blueprint for drone war dominance,” February 07 2024, https://asiatimes.com/2024/02/china-leaks-a-blueprint-for-drone-war-dominance and is even using AI to develop its drone warfare doctrine (B. Drexel/ H. Kelley, “China is flirting with AI catastrophe,” Foreign Affairs, May 30 2023, https://www.foreignaffairs.com/china/china-flirting-ai-catastrophe.

[3] R. Dixon, “Azerbaijan’s drones owned the battlefield in Nagorno-Karabakh—and showed future of warfare,” Washington Post, November 11 2020, https://www.washingtonpost.com/world/europe/nagornokarabkah-

drones-azerbaijan-aremenia/2020/11/11/441bcbd2-193d-11eb-8bda-814ca56e138b_story.html.

[4] Militarnyi, “The Ministry of Defence spent 50 billion UAH on the purchase of drones,” November 09 2024, https://mil.in.ua/uk/news/minoborony-vytratylo-50-mlrd-grn-na-kupivlyu-droniv/.

[5] Ministry of Defence, “For 2024-2025, the Ministry of Defence, in collaboration with the Ministry of Digital Transformation, has already contracted 1,8 million drones totalling nearly UAH 147 billion,” October 29 2024, https://mod.gov.ua/en/news/for-2024-2025-the-ministry-of-defense-in-collaboration-with-the-ministry-of-digital-transformation-has-already-contracted-1-8-million-drones-totaling-nearly-uah-147-billion.

[6] T-Online, “Ukraine hetzt Roboterhunde auf russische Stellungen,“ August 10 2024, https://www.t-online.de/nachrichten/ukraine/id_100465238/ukraine-setzt-roboterhunde-ein-chinesische-modelle-.html.

[7] N-TV, “Roboterhund soll russische Stellungen ausspionieren,“ August 8 2024, https://www.n-tv.de/politik/Roboterhund-soll-russische-Stellungen-ausspionieren-article25146586.html.

[8] See: J. Detsch, “Ukraine goes all-in on ground robots,” Foreign Policy Report, July 17 2024, https://foreignpolicy.com/2024/07/17/ukraine-russia-war-ground-robots-combat/.

[9] M. Samus, “Drone centric warfare,” International Centre for Defence and Security Brief, No. 7 2025, https://icds.ee/wp-content/uploads/dlm_uploads/2025/01/Layout-Samus.pdf.

[10] A. Fenbert, “Ukrainian drones made up over 96% of UAVs military used in 2024, defence minister says,” December 28 2024, https://kyivindependent.com/ukrainian-drones-made-up-over-96-of-uavs-military-used-in-2024-defense-minister-says/.

[11] In Fall 2024, a shipment of Chinese propellers had a defect rate of 90%. (O. Yan, “No more ‘Made in China’: Ukraine inches closer to self-sufficient FPV drone manufacturing,” Militarnyi, December 31 2024, https://mil.in.ua/en/articles/no-more-made-in-china-ukraine-inches-closer-to-self-sufficient-fpv-drone-manufacturing/).

[12] O. Yan, “No more ‘Made in China’: Ukraine inches closer to self-sufficient FPV drone manufacturing,” Militarnyi, December 31 2024, https://mil.in.ua/en/articles/no-more-made-in-china-ukraine-inches-closer-to-self-sufficient-fpv-drone-manufacturing/.

[13] See for example: D. Blinski, “Die Bundeswehr muss sofort 100000 Drohnen anschaffen,“ December 28 2024, https://www.n-tv.de/politik/CSU-Verteidigungsexperte-Florian-Hahn-Die-Bundeswehr-muss-sofort-100-000-Drohnen-anschaffen-article25456033.html; G. Ismar, “Drohnen aus dem Baumarkt für die Bundeswehr“, Süddeutsche Zeitung, July 12 2024, https://www.sueddeutsche.de/politik/bundeswehr-drohnen-ausstattung-lux.TxcvAra7TQqupuv3sL12Bq.

[14] Bundesministerium für Verteidigung, Strategy Paper of the Federal Government on Strengthening the Security and Defence Industry, Berlin 2020, https://www.bmwk.de/Redaktion/DE/Downloads/S-T/strategiepapier-staerkung-sicherits-und-verteidigungsindustrie-en.pdf?__blob=publicationFile&v=4.

[15] Bundesministerium für Verteidigung, National Security and Defence Industry Strategy, Berlin 2024, 4.

[16] “A security and defence industry capable of addressing any and all challenges must be dynamic and scalable to meet the requirements of the Bundeswehr in a rapid and reliable way, both in terms of quality and quantity. In addition, it must be sufficiently agile to allow for rapid and significant capacity increases for production and the provision of services, as well as for allies and close partners with shared values. It must be adaptable and sustainable at all times in the face of evolving security situations.” (Bundesministerium für Verteidigung, National Security and Defence Industry Strategy, Berlin 2024, 5); see for further requirements (Bundesministerium für Verteidigung, National Security and Defence Industry Strategy, Berlin 2024, 5-8).

[17] See, for example: S. Weizenegger, “Defence technology and innovation in Germany,” Atlantik-Brücke Report September 2024, https://www.atlantik-bruecke.org/defense-technology-and-innovation-in-germany/.

[18] C. Johnston, “Breaking down the U.S. Navy’s Hellscape in detail,” Naval News, June 16 2024, https://www.navalnews.com/naval-news/2024/06/breaking-down-the-u-s-navys-hellscape-in-detail/.

[19] U.S. Defence Innovation Unit: “Replicator”, https://www.diu.mil/replicator.

[20] A. Fenbert, “Ukrainian drones made up over 96% of UAVs military used in 2024, defence minister says”, December 28 2024, https://kyivindependent.com/ukrainian-drones-made-up-over-96-of-uavs-military-used-in-2024-defense-minister-says/.

[21] For an extensive description of the development in the Ukrainian Armed Forces see: S. Sumlenny, “The Russian-Ukrainian war: A new way of war and emerging trends,” GIDSresearch No. 5 2024, https://gids-hamburg.de/wp-content/uploads/2024/12/GIDSresearch2024_05_Sumlenny_engl241209.pdf; see also: O. Molly, “Drones in modern warfare – Lessons learnt from the war in Ukraine,” Australian Army Research Center Occasional Paper, No. 29 2024, https://researchcentre.army.gov.au/library/occasional-papers/drones-modern-warfare and S. Pettyjohn/ H. Dennis/ M. Campbell, “Swarms over the Strait – Drone warfare in a future fight to defend Taiwan,” Center for a New American Security, Policy Paper June 2024, https://s3.us-east-1.amazonaws.com/files.cnas.org/documents/Indo-Pacific-Drones_DEFENSE_2024-final.pdf.

[22] Although 3rd party direct funding to domestic production is more efficient and cheaper than donations from abroad.

[23] For example, the STM32F405 chip, which is used to make flight controllers, can be found in refrigerators and children’s toys.

[24] Currently, the setup of an FPV drone changes significantly every 3 months. Drones produced today have almost zero similarities to those produced 12 months ago.

[25] W. Koch, “Innovation zahlt sich aus! – Zyklische Innovation und vernetztes Operieren,“ Behörden Spiegel, February 2025, 40.

[26] The Ukrainian Armed Forces is using the first AI-powered drone (‘Saker Scout’), which autonomously detects targets and records their location. (Defence Express, “Ukraine forces get an AI AI-powered Saker scout drone and its algorithms can solve important problems,” September 4 2023, https://en.defence-ua.com/weapon_and_tech/ukrainian_forces_get_an_ai_powered_saker_scout_drone_and_its_algorithms_can_solve_an_important_problem-7842.html.

[27] A. Rapp, “Die Saluschnyj-Doktrin – Lehren aus der ukrainischen Offensive 2023 und die Zukunft der Drohnenkriegsführung,“ GIDSstatement No. 9 2024, https://gids-hamburg.de/wp-content/uploads/2024/09/GIDSstatement2024_09_Rapp_240930.pdf, 8.

[28] L. Lange, “Ukraine-Krieg: Helsing revolutioniert Drohnenkrieg,“ Telepolis, December 13 2024, https://www.telepolis.de/features/Ukraine-Krieg-Helsing-revolutioniert-Drohnenkrieg-10198142.html.

[29] Jet-stealth-drones ‘JAS-313’ and propeller-driven-drones ‘Qods Mohajer-6’, ‘Ababil-3N’ and ‘Homa’.

[30] T. Newdick, “Iran’s bizarre ‘Aircraft Carrier’ seen in new detail,” August 21 2024, https://www.twz.com/sea/irans-bizarre-aircraft-carrier-seen-in-new-detail; AP, “Iran inaugurates its first drone-carrier warship,” February 6 2025, https://apnews.com/article/iran-drone-carrier-warship-c29e8460ebf2127afb99cf105b4027ba.

[31] See, for example: J. Grady, “Pentagon to industry: Build drones cheaper, faster: Cost per Unit matters,” U.S. Naval Institute News, February 20 2024, https://news.usni.org/2024/02/20/pentagon-to-industry-build-drones-cheaper-faster-cost-per-unit-matters.

[32] See: The New Voice of Ukraine, “‘Twin’ of a ship involved in Zmiinyi Island assault – What is known about Sergey Kotov patrol ship,” March 5 2024, https://english.nv.ua/nation/info-on-one-of-russia-s-most-modern-warships-sergei-kotov-50398532.html.

[33] M. Fornusek, “Ukraine’s Magura drones have reportedly struck 18 Russian ships throughout war,” August 16 2024, https://kyivindependent.com/ukraines-magura-naval-drones/.

[34] V. Kushnikov, “Ukraine Armed Forces destroy Tor air defence system with a drone in the Zaporizhzhia region,” December 5 2024, https://militarnyi.com/en/news/ukrainian-armed-forces-destroy-tor-air-defense-system-with-a-drone-in-the-zaporizhzhia-region/.

[35] D. Malyasov, “Ukrainian drone blow up Russian Tu-22M3 bomber,” April 9 2025, https://defence-blog.com/ukrainian-drone-blow-up-russian-tu-22m3-bomber/.

[36] S. Sumlenny, “The Russian-Ukrainian war: A new way of war and emerging trends,” GIDSresearch No. 5 2024, https://gids-hamburg.de/wp-content/uploads/2024/12/GIDSresearch2024_05_Sumlenny_engl241209.pdf, 5.

[37] S. Pettyjohn/ H. Dennis/ M. Campbell, “Swarms over the Strait – Drone warfare in a future fight to defend Taiwan,” Center for a New American Security, Policy Paper June 2024, https://s3.us-east-1.amazonaws.com/files.cnas.org/documents/Indo-Pacific-Drones_DEFENSE_2024-final.pdf, 55.

[38] O. Yan, “No more ‘Made in China’: Ukraine inches closer to self-sufficient FPV drone manufacturing,” December 2024, https://militarnyi.com/en/articles/no-more-made-in-china-ukraine-inches-closer-to-self-sufficient-fpv-drone-manufacturing/.

[39] S. Sumlenny, “The Russian-Ukrainian war: A new way of war and emerging trends,” GIDSresearch No. 5 2024, https://gids-hamburg.de/wp-content/uploads/2024/12/GIDSresearch2024_05_Sumlenny_engl241209.pdf, 10.

[40] S. Sumlenny, “The Russian-Ukrainian war: A new way of war and emerging trends,” GIDSresearch No. 5 2024, https://gids-hamburg.de/wp-content/uploads/2024/12/GIDSresearch2024_05_Sumlenny_engl241209.pdf, 8.

[41] T-Online, “Ukraine hetzt Roboterhunde auf russische Stellungen,“ August 10 2024, https://www.t-online.de/nachrichten/ukraine/id_100465238/ukraine-setzt-roboterhunde-ein-chinesische-modelle-.html.

[42] S. Sumlenny, “The Russian-Ukrainian war: A new way of war and emerging trends,” GIDSresearch No. 5 2024, https://gids-hamburg.de/wp-content/uploads/2024/12/GIDSresearch2024_05_Sumlenny_engl241209.pdf, 9.

[43] Prom Service, “FPV-Drone repeater ‘Chupacabra’.” https://vkf.com.ua/product/fpv-dron-retranslyator-13-chupakabra-z-akb-8s3p/.

[44] H. Waleed, “Cost-effective chaos: The strategic edge of low-cost drones and the future of military strategy,” September 19 2019, https://defensetalks.com/2024/09/19/; The New Voice of Ukraine, “Ukrainian assault commander says 80 % of strikes rely on drones,” November 2 2024, https://english.nv.ua/russian-war/ukrainian-assault-brigade-commander-highlights-drone-effectiveness-in-combat-50463368.html.

[45] S. Sumlenny, “The Russian-Ukrainian war: A new way of war and emerging trends,” GIDSresearch No. 5 2024, https://gids-hamburg.de/wp-content/uploads/2024/12/GIDSresearch2024_05_Sumlenny_engl241209.pdf, 11.

[46] ASTM (American Society for Testing and Materials), “International: Standard terminology for AM technologies,” F2792-12A.

[47] T. Kruemberg, “Bringing significant rapid manufacturing capacity into the Armed Forces logistics chain,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 6; for further analysis of the differences, see, for example: Wired Consulting/ Microsoft, “The military’s next mission? – Reinvent logistics,” https://custom-solutions.s3.amazonaws.com/WIREDConsultingxMicrosoft_TheMilitary’sNext%20Mission.pdf; B. Straight, “Soldiers win battles, logistics wins wars,” Freight Waves, March 4 2022, https://www.freightwaves.com/news/soldiers-win-battles-logistics-wins-wars; RAISE3D, “Military 3D printing – How is AM changing the defence industry,” January 25 2025, https://www.raise3d.com/blog/military-defense-3d-printing/.

[48] A. Langfeld, “Gaining an edge in military/defence with AM,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 7; 9.

[49] M. May, “Productivity and quality: Automation and machine learning as enablers for industrial AM,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 4-5.

[50] The Polish Armed Forces realised through AM parts for battle tanks replacements – instead on relying on new parts – between 60-75% cost-savings. (M. Wincewicz-Bosy/ K. Kowalski/ G. Stankiewicz, “Conditions for the functioning of logistics support in the Polish Armed Forces of the implementation of AM technology,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 7).

[51] In a case study with the Dutch Armed Forces deployed in Mali, average cost savings – compared to regular shipments – were 47%, savings per part range from 20 to 61% and the inventory level was reduced by 72% on average, when considering only raw materials, inventory levels were still reduced by 66%. (R. Basten, “Printing spare parts at remote locations,” Presentation held at the 1st European Military Additive Manufacturing Symposium, October 12./ 13. 2021, Bonn, 14).

[52] See, for example: L. Holmes Jr., “Additive technology revolutionises defence manufacturing,” National Defence Viewpoint, July 6 2023, https://www.nationaldefensemagazine.org/articles/2023/7/6/additive-technology-revolutionizes-defense-manufacturing; H. Colorado etal., “AM in armor and military applications: Research, materials, processing technologies, perspectives and challenges,” Journal of Materials Research and Technology, No. 27 2023, 3900-3913; K. Stevenson, “Can the military really use 3D printing?,” https://www.fabbaloo.com/news/can-the-military-really-use-3d-printing.

[53] For cases of countries using AM in the military, see for example: M. Prior, “How is AM being adopted in defense,” March 10 2025, https://www.3dnatives.com/en/how-is-additive-manufacturing-being-adopted-in-defense-100320254/#!; European Defense Agency, “EDA pioneers European defense workshop exploring AM,” https://eda.europa.eu/news-and-events/spotlight/spotlight-of-the-month/3d-printing-eda-pioneers-european-defence-workshop-exploring-additive-manufacturing; for a more detailed example see: Bundesamt für Informationstechnik, Ausrüstung und Nutzung der Bundeswehr, “3D-Druck in der Bundeswehr zur Optimierung der Versorgung mit kritischen Ersatzteilen,” Abschlussbericht, June 2022.

[54] See, for example: U.S. Department of Defence, “AM strategy,” Washington D.C. 2021, https://www.cto.mil/wp-content/uploads/2021/01/dod-additive-manufacturing-strategy.pdf.

[55] See, for example: in-flight AM (Naval Postgraduate School, “CAMRE helps Marines take 3D printing to new heights,” July 5 2023, https://nps.edu/-/camre-helps-marines-take-3d-printing-to-new-heights), AM on ships (Trends der Zukunft, “Fregatte ‘Sachsen’: Die deutsche Marine testet den Einsatz von 3D-Druckern auf See,” August 2 2022, https://www.trendsderzukunft.de/fregatte-sachsen-die-deutsche-marine-testet-den-einsatz-von-3d-druckern-auf-see/), even on submarines (AML3D, “AML3D supports AUKUS supply chain with Virgina-Class components,” https://aml3d.com/aml3d-supports-aukus-with-virginia-submarine-component) and for ground forces as well (Bundesministerium der Finanzen Österreich, “2Army – Automated Additive Repair and Manufacturing System,” 2019, https://www.forte-bmf.at/gefoerderte-projekte/detail/2army/; J. Judson, “Still in service: ‘Ex Lab’ is the US Army’s problem-solving MacGyver,” Defense News, October 14 2019, https://www.defensenews.com/digital-show-dailies/ausa/2019/10/14/still-in-service-ex-lab-is-the-us-armys-problem-solving-macgyver/.

[56] M. Ortloff, “Concept for integration of metal FFF to support temporary self-sufficient operation of defence units,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn.

[57] AFE: Additive Fertigungseinrichtung; AFC: Additives Fertigungscenter (see: F. Zimmer, “AM in the German Armed Forces,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./18. 2023, Bonn, 5).

[58] C. Norberg, “Enabling technologies to provide OEM-verified spare parts in the field,” Presentation held at the 1st European Military Additive Manufacturing Symposium, October 12./ 13. 2021.

[59] S. Sumlenny, “The Russian-Ukrainian war: A new way of war and emerging trends,” GIDSresearch No. 5 2024, https://gids-hamburg.de/wp-content/uploads/2024/12/GIDSresearch2024_05_Sumlenny_engl241209.pdf, 7.

[60] Computer-Aided Design.

[61] Original Equipment Manufacturer.

[62] T. Urband, “Intellectual property rights, liability, warranty & how to solve them,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 3-6; see also: S. Rautio/ T. Tuomi/ J. Akmal, “Legal aspects of AM in the military logistics,” Security Dimensions, No. 40 2022, 154-195.

[63] See, for example: M. Heesing, “Export control challenges related to AM,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn.

[64] In the U.S. Department of Defence’s AM strategy, there is a call to “develop and share new business models for AM in contracting and acquisition”. (U.S. Department of Defence, “AM strategy,” Washington D.C. 2021, https://www.cto.mil/wp-content/uploads/2021/01/dod-additive-manufacturing-strategy.pdf, 9).

[65] M. Huber, “AM – A military capability enabler/ European Defense Agency perspective,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 12; see also: B. Müller et al., “NATO-Codification System review of AM,” Legal Study Report, August 2022.

[66] A. Rode, “Introducing AM to the German Armed Forces,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 16.

[67] A. Ade, “Developing skills for the European Defence Sector – Education and training in AM,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 5.

[68] F. Proes, “AM electronics – More functionality at shorter lead time,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 5.

[69] See, for example: X. Luo/ D. Chung, “Electromagnetic interference shielding using continuous carbon fibre, carbon matrix and polymer matrix composites,” Composites, No. 3 1999, 227-231.

[70] S. Rudge, “Pioneering Advanced Manufacturing in defense technology,” Manufacturing Today, April 2024, https://manufacturing-today.com/news/pioneering-advanced-manufacturing-in-defense-technology/; K. Hoschke et al., “Generative and future AI-aided design of functionally graded materials for protection and effectors,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 2.

[71] A. Gagani, “Secure AI software for the industrialisation of AM in the defence sector,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 2; 8.

[72] See, for example: AM-FLOW, “The future of 3D printing lies in automated post-processing: Here’s why,” https://am-flow.com/the-future-of-3d-printing-lies-in-automated-post-processing-heres-why/.

[73] M. May, “Productivity and quality: Automation and machine learning as enablers for industrial AM,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 41.

[74] See for example: M. Meyer/ A. Glas/ M. Eßig, “Wirtschaftlichkeitsanalyse additiver Fertigung als digitales Ersatzteillager,“ Universität der Bundeswehr München Arbeitsgebiet Beschaffung, Arbeitspapier, No. 26 2022, https://www.unibw.de/beschaffung/arbeitspapier-26-wirtschaftlichkeitsanalyse-additiver-fertigung-als-digitales-ersatzteillager.pdf and L. Kayser, “The economics of AM are broken – here’s how to fix it,“ TCT Magazine, May 29 2024, https://www.tctmagazine.com/additive-manufacturing-3d-printing-industry-insights/latest-additive-manufacturing-3d-printing-industry-insights/the-economics-of-additive-manufacturing-don-t-work/.

[76] Although there are new developments to use fibre-optic wire spools to counter Electronic Warfare measures, the majority of the drones will continue to be steered through radio-signals. (D. Trubetskoy, “Glasfaser – der Drohnenkrieg nimmt die nächste Stufe,“ N-TV, February 21 2025, https://www.n-tv.de/politik/Glasfaser-der-Drohnenkrieg-nimmt-die-naechste-Stufe-article25578795.html.

[77] Of those, the costs for the battery are of major importance as they make up about 20 % of the price. Currently, accumulators are also being used in one-way drones. Developing single-use batteries would reduce costs significantly. Another part for major cost savings is the thermal camera – a cheap one could help to reduce costs further. Finally, the flight controllers’ price could lower overall costs in production if they are mass-produced for use in one-way drones.

[78] Business Plans Team, “What are the major operating expenses for drone manufacturers?,” September 30 2024, https://businessplan-templates.com/blogs/running-costs/drone-manufacturing.

[79] M. Wincewicz-Bosy/ K. Kowalski/ G. Stankiewicz, “Conditions for the functioning of logistics support in the Polish Armed Forces of the implementation of AM technology,” Presentation held at the 2nd European Military Additive Manufacturing Symposium, October 17./ 18. 2023, Bonn, 6.

[80] See: I. Valtonen/ S. Rautio/ M. Salmi, “Capability development in hybrid organisations – Enhancing military logistics with AM,” Progress in Additive Manufacturing, No. 7 2022, 1037-1052 and S. Rautio/ I. Valtonen, “Supporting military maintenance and repair with AM,” Journal of Military Studies, No. 1 2022, 1-14.

[81] Through the NATO Digital Library for AM (codename: RAPiD-e) of the NATO Support and Procurement Agency.

[82] PricewaterhouseCoopers, “Cutting-edge, affordable, ready – A vision for Europe’s defence industrial future,” PWC Strategy& Study, 2025, https://securityconference.org/assets/Strategy__A_vision_for_Europe%E2%80%99s_defense_industrial_future_web.pdf.