Abstract: In a less predictable operational environment, resilience and agility are vital requirements for military sustainment. To demonstrate this, we highlight the shortcomings in military supply chains and identify solutions and practices adopted by various organisations to address recognised challenges. Furthermore, there is a need to understand more about new practices and innovations in the business environment that impact supply chains. In conclusion, we highlight several key aspects that military leaders must address to enhance supply chain resilience and agility.

Problem statement: What practices used by large companies can be adopted by military organisations to make military supply chains resilient and agile?

So what?: The military supply chains of NATO’s recent allies face a series of challenges, such as supply disruptions, demand variability, limited visibility and transparency. Large companies encounter many of the same shortages and have developed different practices to mitigate them by using new technologies. Military decision-makers should be informed about best practices and new technologies to enhance the resilience and agility of supply chains.

Source: shutterstock.com/SerGRAY

Introduction

In military operations, the effectiveness of supply chains can often determine the success or failure of missions. As global conflicts become increasingly unpredictable and complex, the concepts of resilience and agility have emerged as critical requirements in military supply chain management.

Logistic operations evolved in tandem with technological advances, primarily to sustain military operations effectively. Logistic operations need to be planned and conducted using information tools that make it harder for the adversary to hinder them. Logistic planners must keep pace with reality as the operational environment becomes contested in multiple domains. As the dynamics of operations tend to develop much faster than before, primarily due to the possibilities of real-time data collection and advanced surveillance and intelligence capabilities, the practices used in logistics must be addressed to respond to new war technologies.

Logistic operations evolved in tandem with technological advances, primarily to sustain military operations effectively.

While resilience and agility can be viewed as distinct concepts, they are fundamentally interconnected in the context of military operations. A resilient supply chain sets the foundation for agility; thus, without the ability to absorb and recover from shocks, a supply chain cannot effectively respond to changes. Additionally, a supply chain that lacks agility may falter in the face of disruptions, undermining its resilience.

This interrelationship emphasises the need for integrated supply chain strategies in military logistics. For example, a military force must maintain sufficient inventory levels for critical supplies to bolster resilience while ensuring that those supplies can be quickly adapted to meet changing operational needs, thus enhancing agility.

Large companies like Renault, Morrisons,[1] Shippeo[2] and many others use a variety of advanced technologies to optimise supply chain management, including Artificial Intelligence, Machine Learning, the Internet of Things, Blockchain Technology and Radio Frequency Identification. The use of these technologies has helped optimise demand forecasting in goods and services, and increase sustainability, thus reducing waste and logistics demand in transportation.

Defining Logistics and Supply Chain Management

Logistics is a process involving as many stakeholders as an organisation considers fit to accomplish its goals. Whether the organisation’s activity is in the realm of commerce or in the military sector, logistics plays a fundamental role in the supply chain management. There is a genuine need for resource procurement and distribution planning to ensure that all goods and services are provided to customers in a timely and cost-effective manner. Logistics is plan-oriented to safeguard product flow from suppliers to consumers. In contrast, supply chain management aims to create the necessary links between the organisation and other stakeholders or entities to achieve effectiveness.[3]

Over the last decades, supply chain management has been seen by theorists as a practical tool to manage and coordinate the entire supply chain, from the initial suppliers of raw materials to a production factory, possibly to a wholesale business or directly to a retailer, and finally to the consumer. Nowadays, due to the objective of achieving synergy throughout the entire supply chain, the process has become more complex and reliant on factors such as information access, competition for resources, and customer satisfaction.

Over the last decades, supply chain management has been seen by theorists as a practical tool to manage and coordinate the entire supply chain.

Military logistics are not much different, to the effect that the provision of goods and services for the fighting forces depends deeply on the availability of suppliers, the timely access to precise information about stocks and distribution, and the protection of sensitive data. In the military domain, customer satisfaction is not just a priority but rather a precondition for operational success. In this case, the customer may be a soldier who needs ammunition, fuel, water, and food, or a tactical unit that requires transportation, evacuation, or resupply. In both civilian and military situations, the operational planning process focuses on delivering the necessary material to the right place at the right time, as cost-effectively as possible.

The military operating environment is complex, uncertain, and vulnerable to numerous factors, including information and intelligence vulnerabilities, adversary threats, competition for resources, and dependence on infrastructure. However, what sets it apart from commercial supply chains is the fact that time is more valuable than profit, because an army without ammunition to fight or fuel to move its equipment has low chances of achieving success in battle. The challenges to military logistics primarily involve the timely and coordinated transportation of materials, such as ammunition, food, or fuel.[4] Supply chain management focuses on delivering profitable outcomes to all stakeholders involved in the chain. For the military domain, sometimes a profitable outcome means gaining time; for example, the combat forces are resupplied faster than the enemy. In that regard, some may argue that the phrasing „demand network management”[5] would be more accurate. For example, Martin Christopher notes that the supply process should focus more on consumer satisfaction rather than market demand. He argues that the process is dependent on multiple suppliers and is not just a linear chain. Military supply chain profitability and customer satisfaction are achieved through effective demand network management, which optimises resources and ensures reliable service delivery.

The concept of Supply Chain Management (SCM) originates from research in marketing, logistics, organisational theory, and operational management. In 1982, R. Oliver and M. Webber were the first to use the term SCM to integrate all logistical and informational processes, from the consumer to primary suppliers. According to these authors, the role of the SCM concept is to ensure that “functional objectives [of top management] do not conflict throughout the logistics chain, as they are reconciled and balanced”.[6] In the same vein, other authors[7] describe the goal of SCM as developing synergy across the entire supply chain by applying a set of practices for the complete management and coordination of supply chains. The benefits gained from implementing SCM most commonly include cost reduction and increased value offered.

The concept of Supply Chain Management originates from research in marketing, logistics, organisational theory, and operational management.

In a summarised view, the supply chain is a sequence of relations that usually begins with the production phase of goods, continues with delivery to retailers, and concludes with delivery to the consumer. In the supply chain, relationships among producers, suppliers, and consumers are complex, and information needs to flow in all directions to ensure continuous improvement in production. Companies have multiple suppliers and consumers in the complex business environment, and supply chain synergy is achieved when final costs are reduced.

Military Supply Chains Shortfalls

As previously emphasised, military supply chains are essential components of logistic operations, ensuring that troops are provided with the necessary supplies, equipment, and services. However, despite their critical importance, military supply chains often encounter various shortfalls and deficiencies that may hinder operational effectiveness.

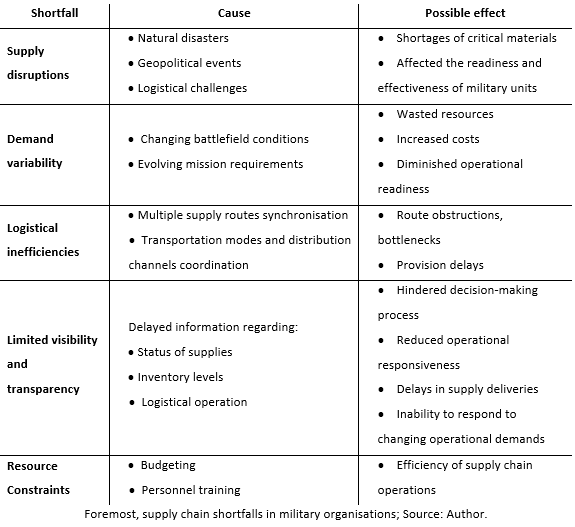

Factors such as natural disasters and geopolitical events can lead to supply disruptions, resulting in critical material shortages that affect the readiness and effectiveness of military units. Meanwhile, demand variability driven by changing battlefield conditions and evolving mission requirements can lead to wasted resources and increased costs, also diminishing operational readiness.

Moreover, logistical inefficiencies, including the weak synchronisation of multiple supply routes and coordination of transportation modes, can create bottlenecks and delays that undermine the timely provision of necessary materials. Limited visibility and transparency hinder decision-making processes, which in turn reduce operational responsiveness and the ability to adapt to dynamic battlefield circumstances. Additionally, resource constraints related to budgeting and personnel training further exacerbate these issues, affecting the overall efficiency of supply chain operations.

For businesses, supply chain shortfalls can produce significant costs, affecting not only their bottom line but also their long-term viability and competitive standing in the market. Addressing these shortfalls proactively, through new practices, is essential for minimising their impact and ensuring operational resilience.

Similarly, considering the military supply chain’s vital role in ensuring operational effectiveness, the various shortfalls identified pose significant challenges to providing troops with the necessary supplies, equipment, and support to ensure mission success. In the early weeks of the invasion of Ukraine, one could observe the operational impact of poor supply chain visibility, the strong reliance upon manual or outdated communication systems, or the lack of real-time data about supply route conditions. The result of a dysfunctional supply chain contributed to the Russian armed forces’ inability to accomplish their mission of conquering Kyiv.[8] Most probably, the operation was designed by Russian strategists to capitalise on surprise and seize the initiative through rapid territorial gains. While the initial execution aligned with the plan, it soon became apparent that critical logistical aspects had not been adequately prepared. The swift advance of Russian forces resulted in overextended supply lines. To preserve operational secrecy, the attack plan was withheld from logistics planners, leaving them without the necessary information to allocate resources in line with Russian logistics doctrine. Additionally, the high tempo of the offensive caused breakdowns in communication systems, with unsecured transmissions intercepted by Ukrainian forces, who then targeted and disrupted Russian resupply convoys.

Considering the military supply chain’s vital role in ensuring operational effectiveness, the various shortfalls identified pose significant challenges to providing troops with the necessary supplies, equipment, and support to ensure mission success.

Military supply chains can better support troops and fulfil their critical mission requirements in unpredictable environments by proactively managing these shortfalls and implementing approaches that bolster resilience and agility.

Resilience in Military Supply Chains

Resilience in a military supply chain refers to the ability to anticipate, respond to, and recover from disruptions while maintaining operational continuity.[9] Given the increasingly unpredictable nature of the military operational environment, driven by the adoption of new technologies, supply chain resilience is crucial for ensuring mission success. To support operational efforts, a resilient supply chain should be able to empower organisations to withstand shocks, recover quickly from disruptions, and thrive in the face of challenges. Several technologies are driving unpredictability in the military operational environment, like AI-powered autonomous systems and drone swarm,[10] or the concept of Mosaic Warfare, referring to new approaches to warfare that offer the potential of gaining a prolonged advantage by making faster and better decisions than adversaries[11].

Resilience is the ability to anticipate, prepare for, respond to, and recover from unexpected disruptions. Some practices used by industry involve proactive risk management, robust contingency planning, flexible sourcing strategies, or establishing parallel military supply chains. For example, Junaid et al. elaborate on the study criteria in their study to identify and assess supply chain risks, such as single-source dependencies or geopolitical instability, in the Pakistani automotive industry. Tools such as the Neutrosophic Analytic Hierarchy Process (AHP) and the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) provide a framework for assessing supply chain risk.[12]

Resilience is the ability to anticipate, prepare for, respond to, and recover from unexpected disruptions.

Some other solutions to a resilient SCM include having a robust contingency plan. This would be achieved by developing alternative sourcing strategies, transportation routes, or production plans to mitigate the impact of disruptions. For example, establishing buffer stocks of critical supplies can provide a cushion against unexpected surges in demand or supply disruptions.

Resilient supply chains are characterised by several key features, such as visibility,[13] or the ability to maintain a clear understanding of the supply chain’s status through real-time data and analytics, flexibility to modify logistics activities, such as sourcing, production, and distribution, and collaboration by building strong relationships and communication channels between suppliers, manufacturers, and distributors.

Additionally, the overall enhancement of supply chain resilience is possible by implementing robust risk management strategies,[14] or diversified supply sources, and flexible logistics capabilities.

Furthermore, resilience also encompasses the readiness to recover from unforeseen setbacks. Containment plans and alternative logistics pathways ensure that military operations can continue, even in the face of supply disruptions. This capability reduces downtime and bolsters the overall effectiveness of military operations.

Agility in Military Supply Chains

The military supply chain’s ability to respond swiftly to changes and demands in operational circumstances proves agility and adaptability. Rapidly shifting conditions—such as changes in enemy tactics, alterations in mission parameters, or emerging threats—require supply chains that can adjust to operations without significant delays. Achieving agility in a military supply chain means the organisation can respond quickly and effectively to unexpected changes in demand and supply. All in one, agility entails achieving responsiveness–as the ability to react swiftly to changing mission requirements or unforeseen events, flexibility–referring to adaptability to changing circumstances, real-time visibility on date information about inventory levels, asset locations, and supply chain conditions, strong partnerships collaboration with multiple suppliers, logistics providers, and other stakeholders.[15] Also, a decentralised decision-making process would empower individuals at different levels of the organisation to make decisions quickly and autonomously.

The military supply chain’s ability to respond swiftly to changes and demands in operational circumstances proves agility and adaptability.

Frequently, agility is achieved through several mechanisms, including real-time data analysis and effective communication with suppliers, manufacturers, and consumers. By rapidly addressing customers’ demands and replenishment flow changes, SCM can efficiently respond to operational requirements, enabling faster decision-making. For instance, during Operation Desert Storm, the U.S. military utilised advanced logistics and supply chain tracking systems. But the tracking systems provided mere data. The real challenge was accessing the processing capability and the ability to deliver information, based on the processed data, on time. Achieving this allowed them to adapt to changing battlefield conditions and ensure the timely delivery of resources.

Agile supply chains in military contexts also facilitate collaboration among various branches of the armed forces and allied nations, ensuring interoperability and efficiency of logistic capabilities. Effective collaboration guarantees that resources are allocated intelligently and that support is provided where it is most needed.

Various Practices Adopted in Business Management

Supply chain management encompasses a range of practices aimed at enhancing overall supply chain synergy. Most business practices are connected to developing new relations between suppliers and consumers to reduce the costs of supply chain deficiencies.

For example, in the early 2000s, Philips Semiconductors implemented a strategy to reduce the number of its direct clients as part of its business transformation efforts. This approach was aimed at optimising its distribution model and focusing on key accounts to improve efficiency and service levels. By consolidating its client base, Philips encouraged its clients to work with distributors, which allowed the company to streamline operations, reduce administrative overhead, and lower costs related to invoicing and debt collection.[16]

In the early 2000s, Philips Semiconductors implemented a strategy to reduce the number of its direct clients as part of its business transformation efforts.

Moreover, Philips Semiconductors conducted a collaborative planning process to reduce the Bullwhip Effect. The Bullwhip Effect is a phenomenon in supply chain management where small fluctuations in demand at the consumer level can lead to larger fluctuations in demand at the wholesaler, distributor, manufacturer, and supplier levels.[17] This outcome, also known as the Forrester effect, often results in inefficient inventory management and increased costs throughout the supply chain. In 1999, Philips Semiconductors acknowledged significant Bullwhip effects within some of its supply chains and began to develop a collaborative planning process and tool to mitigate these issues. The goal was to reduce inventory levels and enhance customer service by aligning its supply chain planning and control with those of its clients.

Other practices aimed at reducing costs include lean manufacturing, a method used to minimise waste within the production process. To define waste, we could examine anything in the production process that the customer is not willing to pay for, such as time, extra space, or the quality of materials.[18] As a lead example of lean manufacturing, the Toyota Production System (TPS) is a comprehensive approach to production management. TPS is a product of gradually accumulated and adopted concepts by Japanese businessmen, such as Taiichi Ohno (Toyota’s chief engineer) and Kikuo Suzumura (Toyota’s manager).[19] At its core, it emphasises maintaining a continuous flow of products within factories to respond flexibly to changes in demand. This approach is known as just-in-time (JIT) production, which involves producing only what is needed, in the necessary quantity, and at the right time. By following this principle, excess inventory and surplus labour are naturally reduced, leading to higher productivity and lower costs.[20] The just-in-time system is a concept focused on aligning the sourcing and use of materials with actual customer demand. When implemented effectively, it helps eliminate various forms of waste, such as excess inventory, unnecessary waiting, inefficient movement, and redundant transportation.

Business strategies focus on reducing added value to the customer by adopting processes that improve SCM. By reducing the number of direct clients, conducting a collaborative planning process, or implementing lean manufacturing solutions, companies managed to reduce inventory levels and eliminate wastes related to transportation issues, thus reducing final costs. The lesson military supply chains may learn is that, by implementing practices like TPS and collaborative planning, the logistics system may become more flexible and profitable, by eliminating wastes, improving the flow of materials and reducing redundancy in the moving and transportation of goods.

Advanced Technologies in Business Supply Chains

In today’s rapidly evolving global market, businesses are increasingly turning to advanced technologies to optimise and transform their supply chain operations. Innovations such as AI, machine learning, the Internet of Things (IoT), blockchain, and big data analytics are reshaping the way supply chains are managed and executed. These technologies enable companies to enhance visibility, improve decision-making, increase efficiency, and respond more effectively to changes in demand and market conditions. As a result, businesses can achieve greater agility, reduce costs, and build more resilient and sustainable supply chains.

In today’s rapidly evolving global market, businesses are increasingly turning to advanced technologies to optimise and transform their supply chain operations.

The Renault company has embraced cutting-edge technologies to enhance its operations, particularly in supply chain management. By adopting artificial intelligence, Renault has modernised its supply chain management and also strengthened its position as a leader in automotive innovation. Renault has integrated advanced technologies such as AI and data analytics to revolutionise its supply chain. In fact, the Renault Group declared its intention to become the first automotive manufacturer fully powered by artificial intelligence, aiming to maximise performance, agility, and innovation.[21]

One of the main benefits of using AI in the supply chain is demand forecasting. Renault employs sophisticated algorithms to analyse historical data and predict future material and component needs. This allows the company to avoid both overstocking and shortages, optimising costs in the process.

Additionally, AI plays a crucial role in logistics optimisation. By monitoring real-time traffic conditions, weather, and other external factors, Renault can dynamically adjust transportation routes, reducing delivery times and minimising environmental impact. This not only boosts efficiency but also supports the company’s sustainability goals.

Another important aspect is predictive maintenance. Renault utilises sensors and AI algorithms to monitor the condition of equipment and vehicles throughout its supply chain. This proactive approach identifies potential failures before they occur, ensuring uninterrupted operations.[22] Moreover, AI technology facilitates closer collaboration with suppliers. Through digital platforms and data analysis, Renault can communicate more effectively with its partners, ensuring seamless coordination and quick responses to any changes or disruptions.

AI technology facilitates closer collaboration with suppliers.

Shippeo, a leading technology company specialising in supply chain visibility and management solutions, won the 2024 Supply Chain Innovation Award for their presentation “Shippeo Ft. Renault: Leveraging Automation to Power a Revolutionary New Automotive Control Tower”.[23] The award was offered by the Council of Supply Chain Management Professionals (CSCMP), a worldwide professional association dedicated to advancing the discipline of supply chain management.[24] Renault Group has collaborated with Shippeo and Google Cloud to develop a transformative Supply Chain Control Tower explicitly tailored for the automotive industry. This innovative platform integrates Shippeo’s real-time transportation visibility with Google Cloud’s AI capabilities to manage inbound logistics across Renault’s 34 global manufacturing plants.

The Control Tower employs Shippeo’s Transportation Process Automation to enhance supply chain resilience. It proactively alerts when the estimated arrival time of parts is projected to occur after the anticipated shortage time at a plant. Subsequently, the system leverages AI-driven configuration to recommend optimal next steps, complete with cost estimates, enabling informed decision-making to maintain uninterrupted production lines.

The aspect of real-time data collection is particularly important in the military supply chain, as it offers solutions to logistic operations redundancy. For example, transportation redundancy translates into delays in providing logistic support, a lack of synchronisation of transportation capabilities, or overwhelmed resupply routes and bottlenecks.

The aspect of real-time data collection is particularly important in the military supply chain, as it offers solutions to logistic operations redundancy.

An example of using innovative tools to increase lean manufacturing is offered by the British supermarket chain Wm Morrison Supermarkets Limited. Morrisons enhances its supply chain operations and leads the way for retail industry supply chain transformation. Blue Yonder provides technical solutions to Morrisons, enabling the UK supermarket chain to discover more effective stock control methods and reduce waste production while better serving its customers.[26]

Morrisons’ stock management systems primarily rely on Blue Yonder’s technology platform. The system enables the company to estimate proper inventory levels for stores so shelves have adequate stock without unnecessary surplus. As a result, the company lowers its expenses and decreases waste.[26]

The tools provided by Blue Yonder effectively reduce waste across various business areas. Morrisons optimises its inventory by assessing how long products last on shelves and customer buying patterns. The technological solutions reduce product disposal, which is both environmentally beneficial and economically advantageous to the business.

Defence-related organisations have adopted blue Yonder’s AI-driven supply chain solutions. For example, Leonardo Helicopters, a leading manufacturer serving both civil and military markets, has implemented Blue Yonder’s Luminate Planning platform to enhance demand forecasting, inventory optimisation, and supply planning for its aftermarket parts.[27]

Solutions like Blue Yonder and Shippeo platform provide real-time visibility, insights and predictions for all transport modes. Platforms like this could prove beneficial for military supply chains, because they can provide fast tracking of military shipments and predict congestion on routes or on the port of embarkation/debarkation of personnel or materiel, by reducing time waste and improving the flow of materials.

Advanced Technologies in Military Supply Chain

The military and private industry have influenced each other in the development and adoption of advanced supply chain technologies, such as those offered by Blue Yonder. However, their paths have distinct origins, with increasing convergence in recent decades. Historically, the military was a pioneer in large-scale logistics and supply management. Major logistical innovations—like standardisation, interoperability, contingency planning and risk management—originated from military needs to supply troops effectively, especially in dynamic and challenging environments. Also, concepts such as inventory management, transportation optimisation, and demand forecasting were developed for military efficiency and later adapted by private industry to improve efficiency and reduce costs. Nowadays, the connection between the military and private industry in the development and adoption of advanced supply chain technologies is symbiotic. Each sector drives innovation that the other can adopt, adapt, and evolve, creating a feedback loop of continuous improvement in logistics resilience and agility.

The integration of advanced technologies in military supply chains transforms operations, providing significant improvements in efficiency, reliability, and responsiveness. AI, the Internet of Things (IoT), blockchain, or robotics enable military organisations to address complex logistical challenges with resilience and agility. AI is revolutionising military logistics by enabling predictive analytics and improving decision-making processes. Military organisations utilise AI to forecast demand for critical resources, including fuel, ammunition, and food supplies. By analysing historical data and operational patterns, AI algorithms can predict future supply needs, ensuring that troops have the necessary resources at the right time. This capability minimises the risk of stockouts and overstocking, ultimately enhancing operational readiness. AI also plays a significant role in logistics optimisation by processing vast amounts of real-time data, including traffic conditions, weather, and enemy action. This optimisation accelerates delivery times and protects personnel and equipment from potential threats.[28]

AI, the Internet of Things, blockchain, or robotics enable military organisations to address complex logistical challenges with resilience and agility.

The IoT enhances military supply chain operations by tracking and monitoring the movement of supplies and equipment. IoT devices, equipped with sensors, provide live data on inventory levels, location, and condition of assets across the supply chain.[29] This visibility allows military organisations to make informed decisions, manage resources efficiently, and quickly address emerging challenges. Moreover, IoT facilitates the predictive maintenance of vehicles and equipment by monitoring their performance and identifying potential malfunctions before they escalate into significant issues. This proactive approach reduces downtime and maintenance costs, ensuring continuous operational flow and enhancing the overall effectiveness of military logistics.[30]

Blockchain technology has emerged as a powerful tool for enhancing transparency and security within military supply chains. By providing a secure and immutable record of all transactions, blockchain ensures the integrity of supply chain data. This capability is especially beneficial in tracking the movement of critical supplies, preventing fraud, and establishing accountability among stakeholders. Additionally, blockchain enhances collaboration among various branches of military logistics and supply chain stakeholders. Smart contracts—automated agreements executed upon predefined conditions—facilitate efficient procurement processes, ensuring timely deliveries while reducing paperwork and administrative burdens.[31]

Robots and automated systems are increasingly integrated into both military and private industry logistics to enhance efficiency and reduce labour costs. Automated vehicles and drones deliver supplies to remote locations, providing rapid resupply without putting personnel at risk. These technologies improve the ability to respond to urgent operational needs while maintaining the safety of military personnel. In warehouses and distribution centres, robotics is employed for inventory management and order fulfilment, allowing military organisations to streamline operations and enhance accuracy in supply distribution.

Robots and automated systems are increasingly integrated into both military and private industry logistics to enhance efficiency and reduce labour costs.

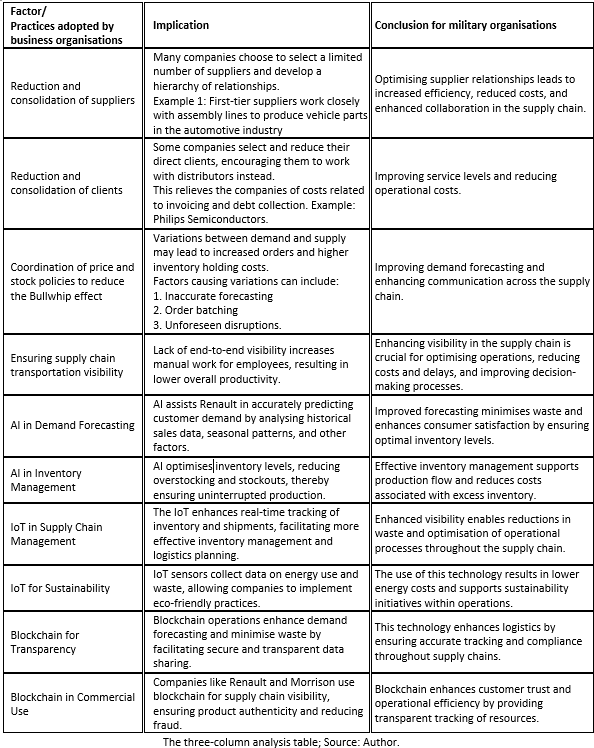

Business models and military practices involving the use of innovation learn from each other, and a clear line of differentiation is hard to draw, as technology develops under both the needs driven by military requirements and also by competition in the private sector. The three-column analysis is a helpful tool that assists military leaders and planners in making informed decisions by systematically assessing various factors and their implications for military operations. It is frequently used to analyse mission objectives, force readiness, threat assessment, but also military logistical operations.

In summary, the practices adopted across various sectors, including reducing and consolidating suppliers and clients, coordinating pricing and stock policies, and integrating advanced technologies like AI, IoT, and blockchain, play a significant role in enhancing supply chain resilience and agility. Each approach addresses specific supply chain challenges, contributing to operational success and improved service levels, with the overall advantage of reducing costs and increasing productivity. For instance, in NATO, one of the practices for consolidating suppliers involves having a Rapidly Usable Enabling Contract (RUEC). The RUEC is a pre-negotiated, flexible contract mechanism that allows NATO organisations or member states to quickly acquire goods or services, especially in response to urgent operational requirements. For this purpose, RUECs are designed to expedite procurement in crisis, contingency, or operational environments, avoid delays associated with traditional competitive tendering, and ensure logistical agility by having contracts “on the shelf” and ready for activation.

Additionally, the use of platforms like those mentioned above may offer significant advantages for military supply chains by enabling the rapid tracking of shipments and forecasting potential congestion along transport routes or at ports of embarkation and debarkation for personnel and equipment.

For military organisations, maintaining resilient and agile supply chains is essential. Through investment in advanced technologies and innovative logistics practices, armed forces can enhance their readiness to address supply chain challenges and ensure that critical resources reach troops precisely when and where they are needed.

Conclusions

The deployment of advanced technologies in the supply chain, particularly by companies like Renault, demonstrates how AI enhances demand forecasting and inventory management, enabling the seamless operation of supply chains. Similarly, IoT and blockchain facilitate real-time tracking, transparency, and sustainability, further improving stakeholder collaboration and overall supply chain performance.

For military organisations, the need for resilience and agility in supply chains is crucial. As military operations become increasingly complex, the ability to adapt quickly to changing circumstances and recover from disruptions is essential for mission success. By investing in advanced technologies and innovative practices, military forces can better prepare themselves to tackle logistical challenges while ensuring that troops receive the critical resources they need when needed.

For military organisations, the need for resilience and agility in supply chains is crucial.

Complementary to this, by mitigating the bullwhip effect through better demand forecasting and enhanced communication, military organisations can optimise their operations and minimise waste. While some military organisations have successfully adopted new technologies into their SCM, there are still many steps to be taken by others. As we previously mentioned, logistical shortfalls can have unwanted consequences, including resupply disruptions and delays, increased costs, poor coordination of transportation modes, and limited visibility and transparency. Embracing technology, fostering strong partnerships, and implementing robust logistical frameworks will enable military organisations to thrive in uncertain environments. As seen in the example of the Kiev battle, the undesired effect on the supply chain in that case was the logistic disruption and failure to support operational objectives.

The strategic application of these innovations strengthens defence operations and ensures that armed forces maintain operational readiness and effectiveness in contemporary warfare. The ongoing development and integration of advanced supply chain strategies will be vital for meeting the future challenges faced by military logistics.

Major Ana-Maria Merlusca, Superior Instructor, Ph.D. candidate, Command and Staff Faculty, “Carol I” National Defence University. Research interests: military transportation, autonomous vehicles, and logistics planning. Earlier publications: „Digital technologies used in the field of military transport”, in Bulletin of “Carol I” National Defence University No.2/2024, „Theoretical-practical incongruences of logistic support in the fight for the conquest of Kiev”, in Romanian Military Thinking Conference 2024. Academic fields: logistics, marketing, transportation.

Matei-Alexandru Ropotan, military student in “Carol I” National Defence University, Bucharest, specialising in Quartermaster studies. Graduated from “Vasile Alecsandri” National College, with a specialisation in Mathematics and Computer Science. Interests: military logistics and the integration of emerging technologies in defence. Academic fields: logistics, education, environment.

The views contained in this article are the authors’ alone and do not represent the views of the National Defence University “Carol I”.

[1] Morrison Express, Supply chain solutions, last modified January 05, 2025, https://www.morrisonexpress.com/supply-chain-solutions/.

[2] Shippeo Press release, 08/10/2024, last modified January 05, 2025

[3] Martin Christopher, Logistics & Supply Chain Management, 4. ed (Harlow: Financial Times Prentice Hall, 2011), 2.

[4] J Haden Boone et al., “Military Logistics Planning for Expeditionary Warfare,” n.d., 2.

[5] Christopher, Logistics & Supply Chain Management, 16.

[6] Keith Oliver and Michael D. Webber, “Supply-Chain Management: Logistics Catches up with Strategy,” in The Roots of Logistics : A Reader of Classical Contributions to the History and Conceptual Foundations of the Science of Logistics (Berlin : Springer, 2012), 66.

[7] Tom Vollman, Carlos Cordon, and Hakon Raabe, “Managementul Lanțului de Aprovizionare,” in Cum Să Stăpânești Managementul La Perfecție (Rentrop&Straton, 2000), 278.

[8] Ana-Maria Merlușcă and Cristian-Octavian Stanciu, “Theoretical-Practical Incongruences of Logistic Support in the Fight for the Conquest of Kyiv,” Romanian Military Thinking 2024, no. 4 (December 31, 2024): 74, https://doi.org/10.55535/RMT.2024.4.04.

[9] Editorial Team, “Enhancing Supply Chain Resilience: Strategies for Sustainable Success,” MilitarySphere.Com (blog), 2024, https://militarysphere.com/supply-chain-resilience-strategies/?utm_source=openai.

[10] “Pentagon Stares down ‘Drone Swarm’ Threat,” AXIOS, 2024, https://www.axios.com/2024/03/15/drone-swarms-ai-military-war.

[11] Bryan Clark, Dan Patt, and Harrison Schramm, “Mosaic Warfare Exploiting Artificial Intelligence And Autonomous Systems To Implement Decision-Centric Operations” (Center For Strategic And Budgetary Assessments, 2020), vi.

[12] Muhammad Junaid et al., “A Neutrosophic AHP and TOPSIS Framework for Supply Chain Risk Assessment in Automotive Industry of Pakistan,” Sustainability 12, no. 1 (December 24, 2019): 7, https://doi.org/10.3390/su12010154.

[13] Ghulam Qader et al., “Industry 4.0 Enables Supply Chain Resilience and Supply Chain Performance,” Technological Forecasting and Social Change 185 (2022), https://doi.org/10.1016/j.techfore.2022.122026.

[14] Saurabh Ambulkar, Jennifer Blackhurst, and Scott Grawe, “Firm’s Resilience to Supply Chain Disruptions: Scale Development and Empirical Examination,” Journal of Operations Management 33–34 (2015): 111–22, https://doi.org/10.1016/j.jom.2014.11.002.

[15] Juan M. Hernández and Carmen Pedroza, “The Influence of the Network Topology on the Agility of a Supply Chain” (arXiv, 2016), 6, https://doi.org/10.48550/ARXIV.1611.10094.

[16] Vollman, Cordon, and Raabe, “Managementul Lanțului de Aprovizionare,” 278.

[17] Ton De Kok et al., “Philips Electronics Synchronises Its Supply Chain to End the Bullwhip Effect,” Interfaces 35, no. 1 (February 2005): 38, https://doi.org/10.1287/inte.1040.0116.

[18] Frank Voehl et al., The Lean Six Sigma Black Belt Handbook: Tools and Methods for Process Acceleration, 0 ed. (Productivity Press, 2013), 101, https://doi.org/10.1201/b15163.

[19] Phil Ledbetter, The Toyota Template: The Plan for Just-in-Time and Culture Change beyond Lean Tools (Boca Raton, FL: CRC Press, 2018), 1.

[20] Voehl et al., The Lean Six Sigma Black Belt Handbook, 103.

[21] “FutuRGen Insight – ”AI: The New Frontier of the Automotive Revolution”,” Renault Group, 2025, https://www.renaultgroup.com/en/magazine/technology/futurgen-insight-ai-the-new-frontier-of-the-automotive-revolution?form=MG0AV3.

[22] “Revolutionising Renault: AI’s Impact on Supply Chain Efficiency,” Dataiku, 2024, https://blog.dataiku.com/revolutionizing-renault-ais-impact-on-supply-chain-efficiency?form=MG0AV3.

[23] “Shippeo Press Release,” 2024, https://cscmp.informz.net/informzdataservice/onlineversion/ind/bWFpbGluZ2luc3RhbmNlaWQ9NDI3NTUyMCZzdWJzY3JpYmVyaWQ9MzkzNTc2MjU0.

[24] “Council of Supply Chain Management Professionals (CSCMP),” 2013, https://cscmp.org/CSCMP/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms.aspx?hkey=60879588-f65f-4ab5-8c4b-6878815ef921.

[25] “Morrisons Simplifies Fresh Food Clearance with Blue Yonder,” Blue Yonder, n.d., https://blueyonder.com/customers/morrisons?form=MG0AV3.

[26] Blue Yonder, Morrisons puts the customer at the heart of every decision (n.d.).

[27] “News Blog Leonardo Helicopters Pilots Supply Chain Planning Transformation with Blue Yonder,” Blue Yonder Media Centre, 2021, https://media.blueyonder.com/leonardo-helicopters-pilots-supply-chain-planning-transformation-with-blue-yonder/?utm_source=chatgpt.com.

[28] “The Future of Military Supply Chain Management: AI Applications Unveiled,” Military Sphere, 2024, https://militarysphere.com/ai-applications-in-military-supply-chain-management/?form=MG0AV3.

[29] “IoT in Supply Chain: Benefits, Challenges, and Real-World Examples,” Webbylab (blog), n.d., https://webbylab.com/blog/iot-in-supply-chain/?form=MG0AV3.

[30] “Future of Army Logistics | Exploiting AI, Overcoming Challenges, and Charting the Course Ahead,” U.S. Army, 2023, https://www.army.mil/article/267692/future_of_army_logistics_exploiting_ai_overcoming_challenges_and_charting_the_course_ahead?form=MG0AV3.

[31] “Blockchain for Military Logistics,” U.S. Army, 2019, https://www.army.mil/article/227943/blockchain_for_military_logistics?form=MG0AV3.